Drop forging manufacturer

sales@dropforging.net

sales@dropforging.net

Drop Forging is a metalworking process that deforms metal by applying pressure, usually at high temperatures. So, temperature control is a necessary step in drop forging production, and there is a strict temperature control requirement on each type of forged metal. For instance, steel forging usually requires to heat billets to 950°C and 1250°C, while aluminum forging and brass forging have lower heating temperature requirement. Aluminum forging can be performed at temperatures between 350°C and 500°C, and the ideal forging temperatures of brass forging range from 600°C to 950°C.

CFS Forge has been in drop forging industry for over 25 years, we usually control the temperature for forging production by induction heating furnace. This heating equipment can provide rapid and uniform heating, allowing precise control over the temperature and heating rates of the forging billets, thus improving consistency.

Drop forging is an excellent process for making high-strength components like turnbuckle bodies. Known for its ability to enhance metal properties, drop forging ensures the strength, load-carrying capacity, and precision structural hardware needs.

CFS Forge is the top leading China drop forging company, we are very familar with the manufacturing process of drop forged turnbuckle bodies. In this article, we would like to share all that you might want to know about drop forging technique and its process to create turnbuckle bodies.

With the development of forging technique, aluminum alloys are more and more popular in forging production due to their great strength, light weight, and corrosion resistance. CFS Forge is the top China aluminum forging company, specializing producing custom forged aluminum parts in various alloys, such as 2014, 6061, 6063, 6082, and 7075 alloys. Among these alloys, each has its special features and advantages. In this article, we would like to compare 6082 and 7075 aluminum alloys for forging, which can help our customers to choose a proper alloy for their project.

Both 6082 and 7075 aluminum alloys offer unique advantages for drop forging applications. 6082 excels in corrosion resistance, weldability, and cost-effectiveness, making it ideal for structural components and environments where these factors are critical. On the other hand, 7075 provides unmatched strength and hardness, suitable for high-stress applications in the aerospace and defense industries. Understanding the specific requirements of your application is essential in making the right choice. CFS team can recommend the best suitable aluminum alloy for your forged item.

Motorcycle pistons is an important component for generating power in vehicles and work under high temperature and high pressure conditions. It is also a critical component in maintaining normal workflow. CFS Forge is the top leading forging manufacturer in China, we have rich experience in forging aluminum pistons for motorcycles. So, we are very familar with the whole manufacturing process of forging aluminum motorcycle pistions.

Are you looking for high-performance forged aluminum pistons for your motorcycle? CFS Forge is your reliable manufacturer for custom forging solutions that meet the highest standards of quality and durability. Would like to know how we can help your project? Contact us today and send us your inquiry for an instant quote now!

CFS Forge can customize your special designed forged aluminum motorcycle parts with precise dimensions and good surface finish. Besides forging, we can also provide precision machining and surface anodizing services for finished motorcycle parts. Our strict quality control procedure enables us to deliver high quality products and reasonable prices. If you are looking for a good forging company for your motorcycle parts, pls contact us to request a free quote first!

CFS Forge is a professional forging manufacturer, offering top-quality forged steel towballs designed for safety, reliability, and longevity. With advanced forging equipments and strict quality control, CFS Forge is your trusted partner for all your towball needs. Whether you're towing a trailer or caravan, we can customize exactly to meet your specifications . Contact us today to learn more about capabilities and request a free quote shortly.

Another reason for choosing aluminum forging is its advanced corrosion resistance. Mechanical cable lugs are often exposed to diverse environmental conditions, including moisture and chemicals. Aluminum's natural ability to form a protective oxide layer ensures that the lugs remain unaffected by corrosion, safeguarding their performance and longevity. This resistance makes aluminum-forged lugs an ideal choice for outdoor installations and in harsh environment applications.

In this comprehensive guide, we'll introducec why aluminum forging is the preferred method for creating high-performance motorcycle footpegs and how CFS Forge can make custom forged aluminum footpegs to meet your special requirements.

The crank arm is a crucial component of a bicycle's drivetrain system, responsible for transferring the cyclist's leg power into the chain, thus propelling the bicycle forward. Essentially, crank arms are levers connecting the pedals to the bottom bracket spindle, forming a vital connection between the rider and the bike's drivetrain.

The choice of manufacturing method plays a significant role in the performance, durability, and weight of a crank arm. Forged aluminum is preferred for crank arms because of its superior structural integrity and lightweight characteristics. Aluminum forging creates parts that are stronger and more reliable than those produced by other manufacturing methods like casting or machining.

Forged aluminum crank arms offer a superb stiffness-to-weight ratio, which is a critical parameter for efficient power transfer. They can also withstand high stress and strain levels without deformation, an attribute essential for high-performance cycling applications.

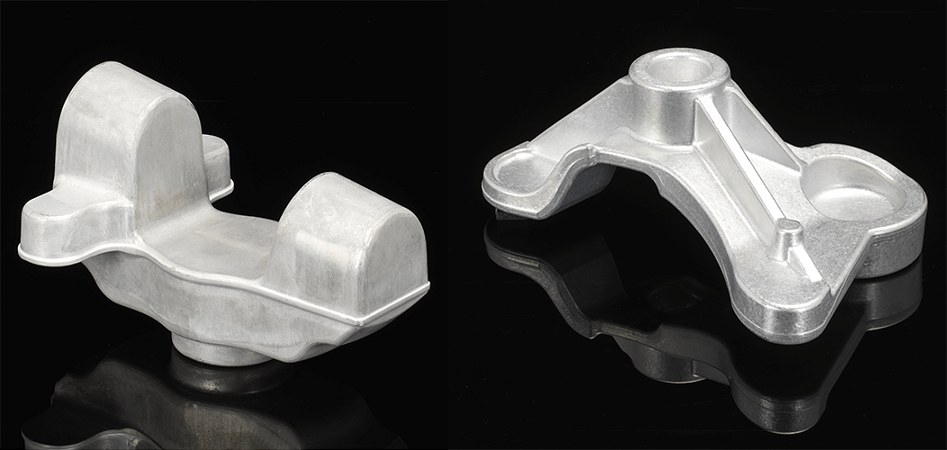

Drop forging is a suitable manufacturing process for ball joint housings. Forging delivers a range of benefits in the production of ball joint housings, particularly due to the process's ability to significantly enhance the properties and performance of the manufactured component. As a reliable drop forging manufacturer in China, CFS Forge can custom forge all types of ball joint housings to meet your drawing's specifications.

There are two types of tie rod ends - inner and outer. The inner tie rod ends are attached to the steering rack, while the outer tie rod ends connect the inner tie rod ends to the steering knuckle. Together, they ensure the driver can steer the vehicle accurately and smoothly.

However, tie rod ends are subjected to constant stress and can wear down over time, leading to steering problems. Therefore, the manufacturing process of these parts becomes critical to ensure they are robust, reliable, and durable. Among various manufacturing methods, the drop forging process is an ideal process in the automotive industry, which can enhance the tie rod end's strength and durability.

Drop forging produces parts that have excellent mechanical properties, such as high strength and toughness. The process creates a tightly packed grain structure that enhances the strength and durability of the material. As a result, automotive components produced using drop forging are highly resistant to wear and tear, as well as to fatigue failure.