Drop Forging Advantages

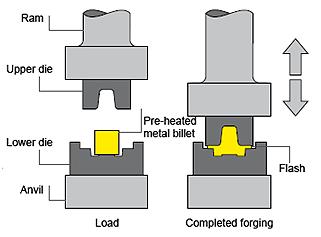

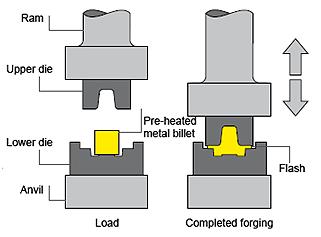

Drop forging is a processing way that using high strength die, metal blank will be plastic deformed on forging press, then we will obtain the required shape, size and internal quality. In deformation process, due to the limitation of the metal flow by the fuction of chamber model, thus we will see the drop forged parts whose shape accords with the mould chamber.

Below are the advantages of drop forging:

Below are the advantages of drop forging:

1) The production efficiency is higher. In the chamber cavity of mould, the deformation of the metal is proceeding, so we can quickly obtain the required shape.

2) Complex shaped metal parts can be forged with this process, and the distribution of metal flow line is more reasonable. Besides, drop forging process can improve the serving life of parts.

3) The size of drop forgings is accurate, we can also achieve better surface quality, and smaller machining allowance.

4) This process will also save metal material and reduce machining work. Under the condition of enough batch, it will reduce the cost of spare parts.

5) The production operation is easy, so the work force is low.

Below are the advantages of drop forging:

Below are the advantages of drop forging:1) The production efficiency is higher. In the chamber cavity of mould, the deformation of the metal is proceeding, so we can quickly obtain the required shape.

2) Complex shaped metal parts can be forged with this process, and the distribution of metal flow line is more reasonable. Besides, drop forging process can improve the serving life of parts.

3) The size of drop forgings is accurate, we can also achieve better surface quality, and smaller machining allowance.

4) This process will also save metal material and reduce machining work. Under the condition of enough batch, it will reduce the cost of spare parts.

5) The production operation is easy, so the work force is low.

sales@dropforging.net

sales@dropforging.net